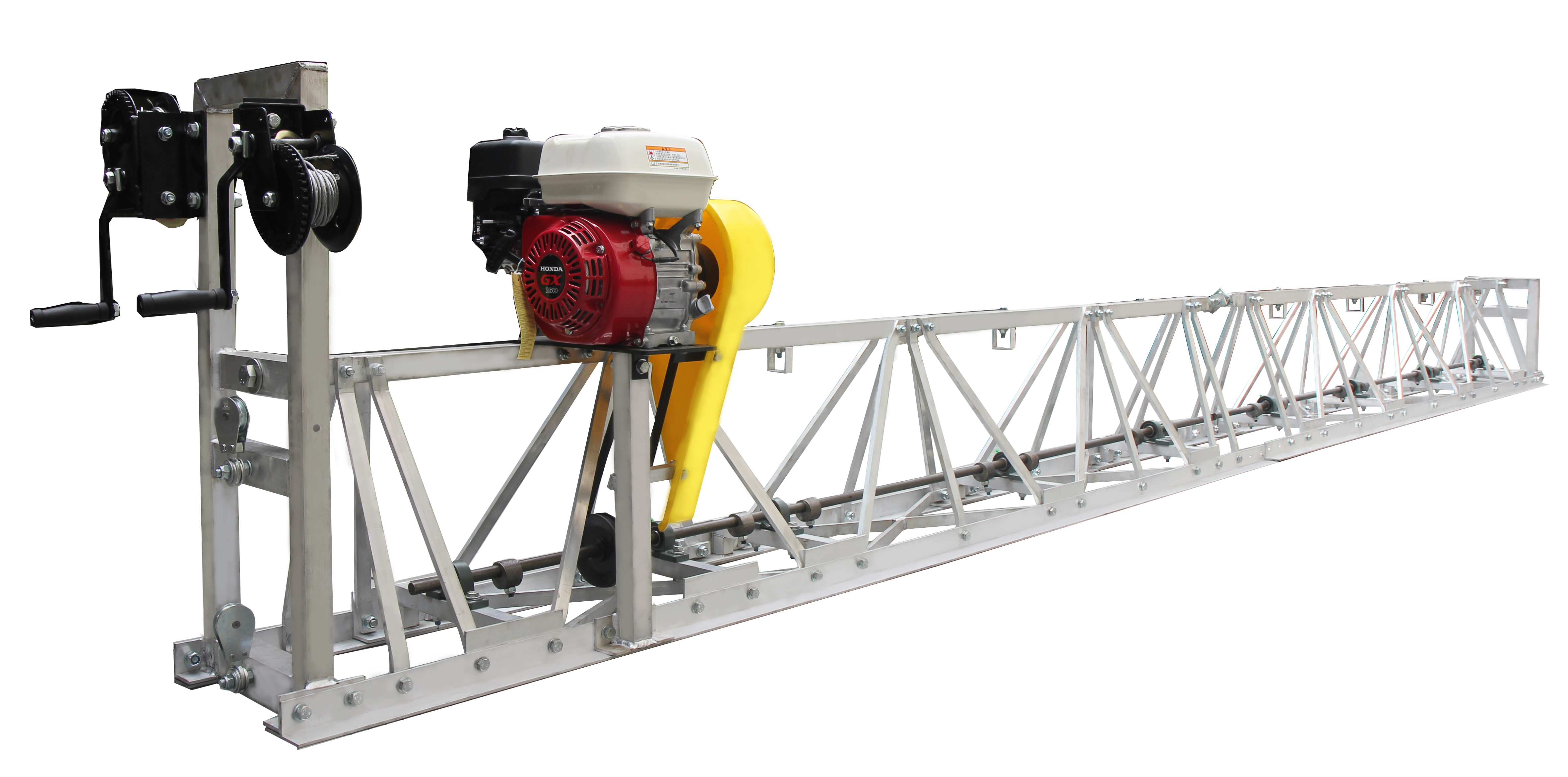

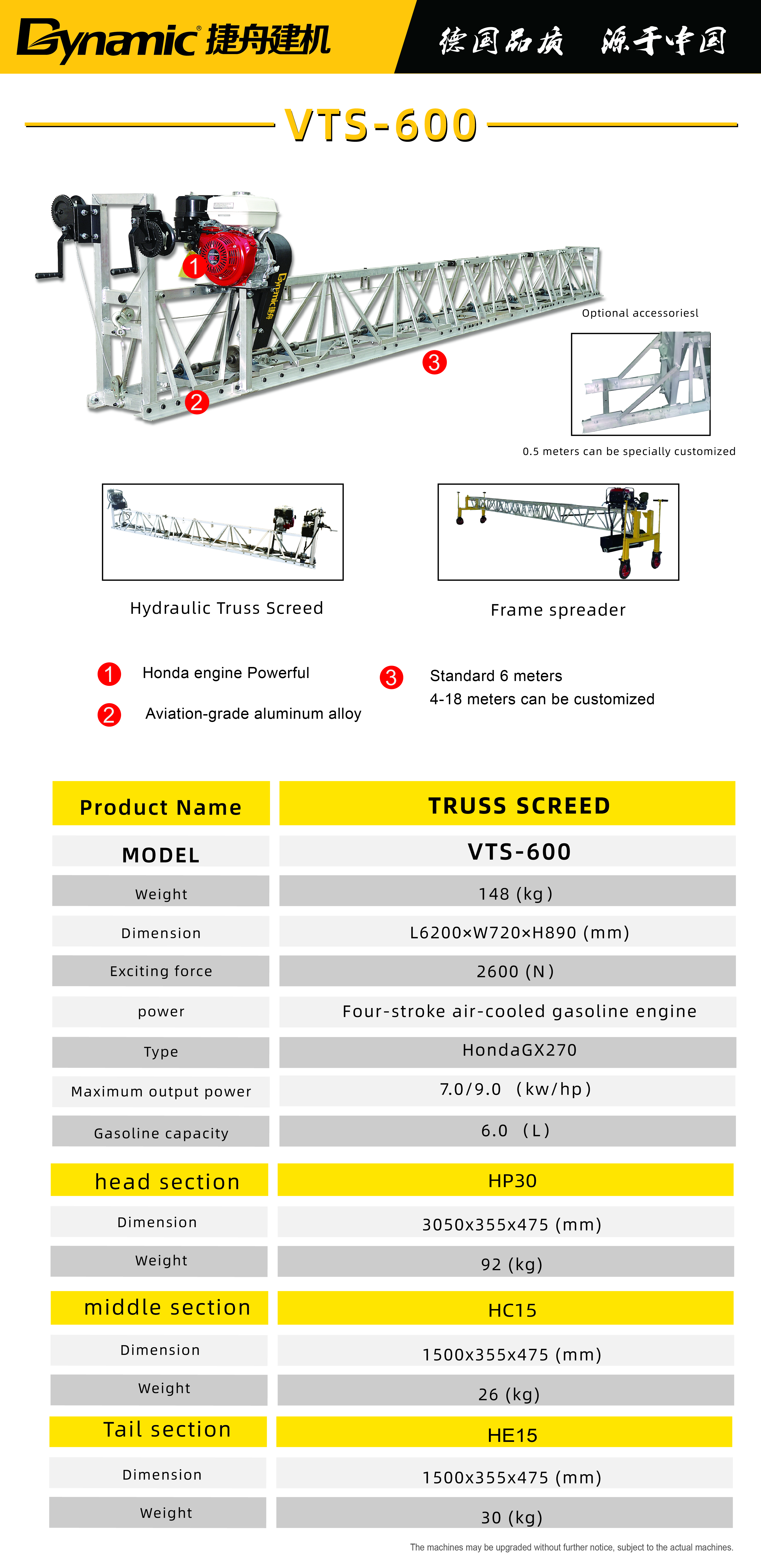

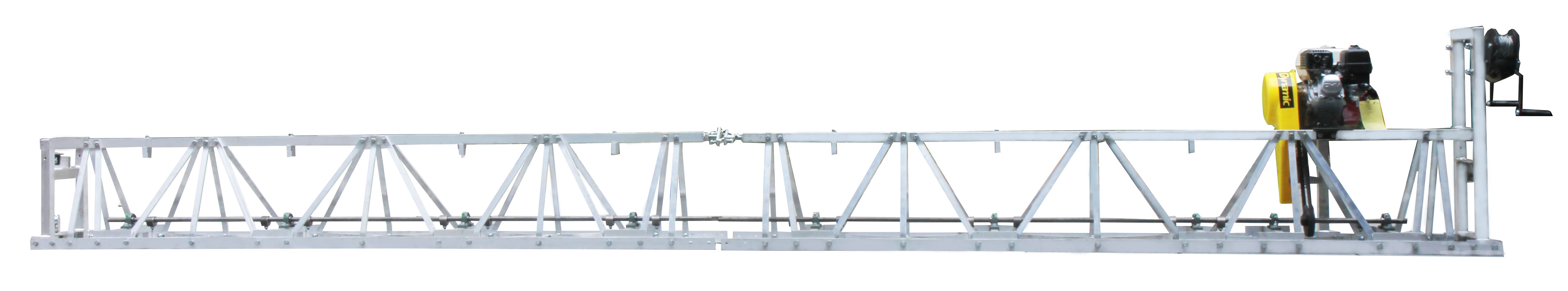

The VTS-600 Concrete Truss Screed is designed to simplify the concrete surface leveling process, making it an indispensable tool for construction projects of all sizes. Its aluminum trusses with a span of 6 meters provide excellent rigidity and stability, ensuring the concrete is perfectly flat. This machine is a game changer for the construction industry and offers numerous advantages that set it apart from traditional leveling methods.

One of the main advantages of the VTS-600 concrete truss screed is its efficiency. With its extended truss length, it can cover a larger area at once, significantly reducing the time and labor required to level concrete. This not only speeds up the construction process but also minimizes disruptions, resulting in smoother project timelines and deadlines.

In addition to efficiency, the VTS-600 concrete truss screed offers unparalleled precision. The aluminum trusses were carefully designed to ensure an even distribution of concrete, resulting in a flat surface with minimal undulations. This level of precision is critical for projects that require high-quality finishes, such as industrial floors, warehouse facilities, and large walkways.

In addition, the VTS-600 concrete truss screed is versatile and suitable for a variety of concrete screed applications. Whether it’s a road, an airport runway or an industrial floor, the machine can adapt to a variety of project requirements, making it a valuable asset to contractors and construction companies.

The lightweight nature of the aluminum trusses also contributes to the machine’s maneuverability and ease of use. Despite its impressive span, the trusses are designed to be lightweight without compromising strength, making them easy to transport and assemble on site. This feature increases the overall efficiency of the machine and allows the operator to navigate and operate with ease.

In addition, the VTS-600 concrete truss screed is equipped with advanced technology that further enhances its performance. From precise leveling controls to ergonomic design elements, every aspect of the machine has been carefully designed to optimize the concrete leveling process. Not only does this improve the quality of the finished surface, it also reduces the margin of error, resulting in cost savings and improved project outcomes.

In terms of sustainability, the VTS-600 concrete truss screed also offers environmental benefits. It contributes to more sustainable construction methods by simplifying the concrete leveling process and minimizing material waste. This is in line with the growing emphasis on environmentally friendly practices within the industry, making this machine the first choice for environmentally friendly projects.

The VTS-600 concrete truss screed is also designed with durability in mind. It’s made from high-quality materials and engineered to withstand the rigors of a construction site and be built to last. This longevity means contractors can save money in the long term, as the machine requires minimal maintenance and is designed to handle the demands of heavy-duty use.

In summary, the VTS-600 concrete truss screed represents a significant advancement in concrete screed technology. Its 6-meter aluminum trusses, combined with its efficiency, precision, versatility and sustainability, make it a game-changing solution for construction projects. As the construction industry continues to evolve, innovative machines like the VTS-600 Concrete Truss Screed are changing the way concrete surfaces are smoothed, setting new standards for quality and efficiency.

Post time: May-06-2024