In the world of construction, achieving a perfectly level concrete surface is crucial for both aesthetic and functional purposes. Whether it’s for a driveway, a floor slab, or a foundation, the quality of the concrete finish can significantly impact the durability and appearance of the structure. One of the most effective tools for achieving this level of precision is the Gasoline Laser Concrete Vibrating Screed Machine. This innovative equipment combines advanced technology with practical functionality, making it an essential asset for contractors and builders alike.

Understanding the Basics: What is a Gasoline Laser Concrete Vibrating Screed Machine?

At its core, a Gasoline Laser Concrete Vibrating Screed Machine is designed to level freshly poured concrete. It utilizes a vibrating screed mechanism that helps to distribute the concrete evenly while simultaneously eliminating air pockets and ensuring a smooth finish. The incorporation of laser technology allows for precise leveling, ensuring that the surface meets the required specifications.

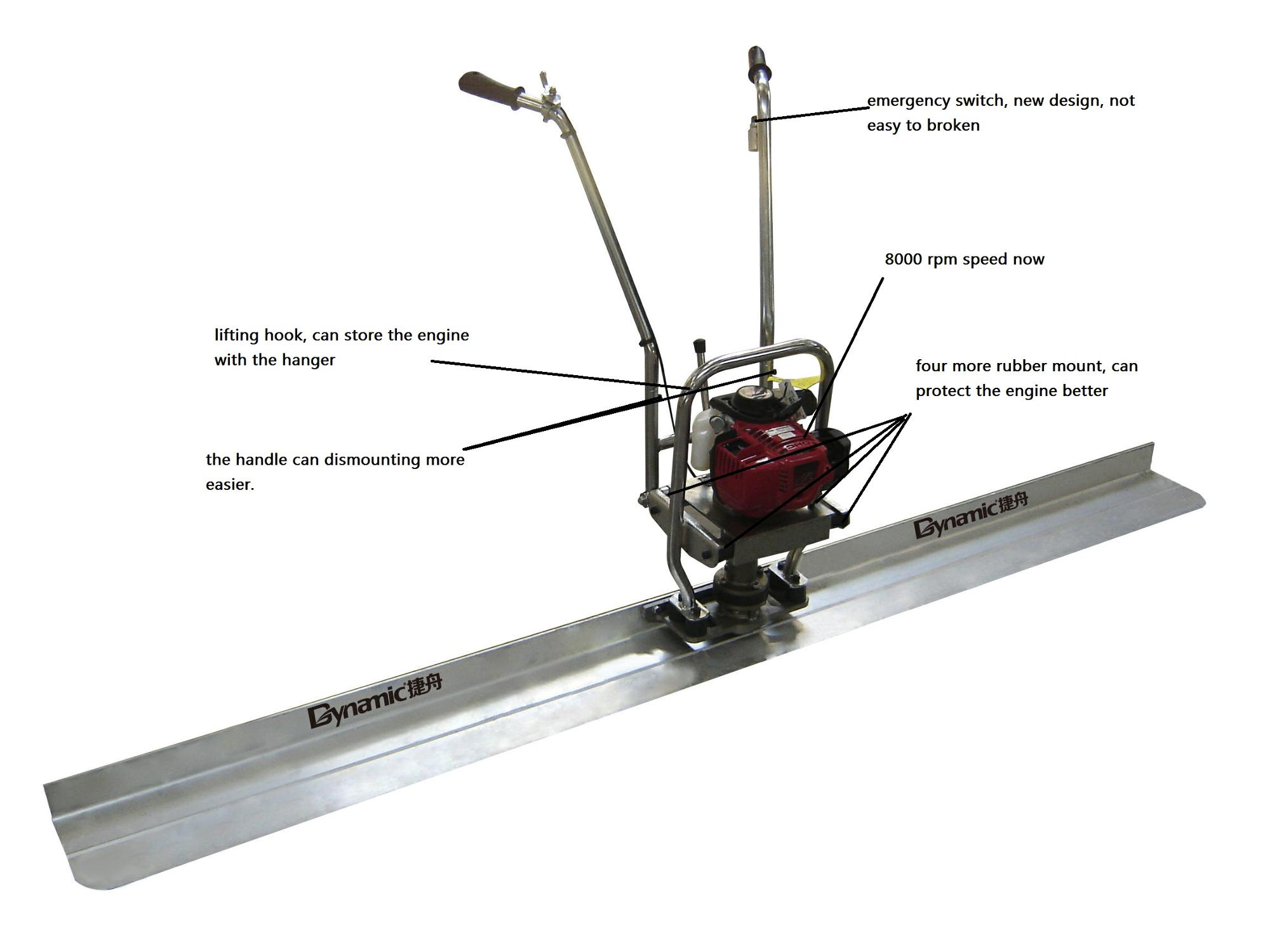

Key Components of the Machine

1. Gasoline Engine: The power source for the machine, typically a reliable gasoline engine, provides the necessary energy to operate the screed and the vibrating mechanism. This makes it suitable for outdoor use where electricity may not be readily available.

2. Laser Leveling System: The laser system projects a beam that serves as a reference point for leveling. This technology allows operators to achieve a high degree of accuracy, ensuring that the concrete surface is perfectly flat.

3. Vibrating Screed Blade: The screed blade is the part of the machine that directly interacts with the concrete. It vibrates to help settle the concrete mix, reducing the likelihood of air bubbles and ensuring a dense, solid finish.

4. Control System: Modern machines come equipped with user-friendly controls that allow operators to adjust the speed and vibration intensity, tailoring the operation to the specific requirements of the job.

Advantages of Using a Gasoline Laser Concrete Vibrating Screed Machine

1. Enhanced Precision

The integration of laser technology into the screeding process significantly enhances precision. Traditional methods of leveling concrete often rely on manual techniques, which can lead to inconsistencies. The laser system ensures that every part of the surface is leveled to the same height, reducing the risk of dips and bumps.

2. Increased Efficiency

Using a Gasoline Laser Concrete Vibrating Screed Machine can drastically reduce the time required to level concrete surfaces. The machine can cover large areas quickly, allowing contractors to complete projects faster and move on to the next job. This efficiency translates to cost savings and increased productivity.

3. Improved Concrete Quality

The vibrating action of the screed helps to eliminate air pockets and voids within the concrete mix. This results in a denser, stronger surface that is less prone to cracking and other forms of damage. The overall quality of the concrete is significantly improved, leading to longer-lasting results.

4. Versatility

These machines are versatile and can be used for various applications, including residential, commercial, and industrial projects. Whether you’re pouring a small patio or a large warehouse floor, the Gasoline Laser Concrete Vibrating Screed Machine can adapt to the task at hand.

5. Reduced Labor Costs

By automating the screeding process, contractors can reduce the number of laborers needed on-site. Fewer workers are required to achieve the same level of quality, which can lead to significant savings in labor costs.

How to Operate a Gasoline Laser Concrete Vibrating Screed Machine

Operating a Gasoline Laser Concrete Vibrating Screed Machine requires some training and understanding of the equipment. Here’s a step-by-step guide to help you get started:

Step 1: Preparation

Before using the machine, ensure that the concrete mix is ready and that the area is clear of debris. Set up the laser leveling system according to the manufacturer’s instructions, ensuring that it is properly aligned with the desired height.

Step 2: Start the Engine

Start the gasoline engine and allow it to warm up. Familiarize yourself with the control panel, including the throttle and vibration settings.

Step 3: Position the Screed

Place the vibrating screed blade at one end of the area to be leveled. Ensure that the blade is in contact with the concrete surface.

Step 4: Begin Screeding

Engage the vibration function and slowly move the screed across the surface. Use a steady, even motion to ensure that the concrete is leveled consistently. Keep an eye on the laser beam to maintain the correct height.

Step 5: Repeat as Necessary

Continue to move the screed across the area, overlapping each pass slightly to ensure complete coverage. Adjust the vibration settings as needed to achieve the desired finish.

Step 6: Finishing Touches

Once the entire area has been leveled, you may need to perform additional finishing work, such as troweling or applying a sealant, depending on the project requirements.

Maintenance Tips for Longevity

To ensure that your Gasoline Laser Concrete Vibrating Screed Machine remains in optimal condition, regular maintenance is essential. Here are some tips to keep in mind:

1. Regular Cleaning: After each use, clean the screed blade and other components to remove any concrete residue. This will prevent buildup and ensure smooth operation.

2. Check Engine Oil: Regularly check and change the engine oil according to the manufacturer’s recommendations. This will help maintain engine performance and longevity

3. Inspect the Laser System: Ensure that the laser leveling system is functioning correctly. Replace batteries or components as needed to maintain accuracy.

4. Tighten Loose Parts: Periodically inspect the machine for any loose bolts or components. Tightening these will prevent unnecessary wear and tear.

5. Store Properly: When not in use, store the machine in a dry, sheltered area to protect it from the elements.

Conclusion

The Gasoline Laser Concrete Vibrating Screed Machine is a game-changer in the construction industry, offering unparalleled precision, efficiency, and quality in concrete leveling. By harnessing the power of gasoline engines and laser technology, this machine simplifies the screeding process, making it an invaluable tool for contractors and builders. With proper operation and maintenance, it can significantly enhance the quality of concrete surfaces, ensuring that projects are completed to the highest standards. Whether you’re a seasoned professional or a DIY enthusiast, investing in a Gasoline Laser Concrete Vibrating Screed Machine is a decision that will pay off in the long run.

Post time: May-16-2025